Cable & Wire Extrusion Lines

Across the world, Supermac is a reputed cable extruder machine manufacturer & supplier. It is known for its revolutionary product line carrying the best amalgamation of quality, cost, and delivery. Its products such as the extrusion machine for THHN wires and extrusion machine for Lan cables are trusted by the global cable industry cementing the top space for brand Supermac.

Each extrusion machine for building wires is not only fully guarded but also incorporated with IoT enabled hardware while following the industry 4.0 norms. The extrusion lines are available in single/dual/triple extrusion system with the ability to manage a wide range of products. The extrusion lines come with user-friendly interface and a self-diagnostic feature.

The Supermac extrusion lines provide high production speed, optimized processing, low energy consumption, settings customization, and work with versatile materials.

-

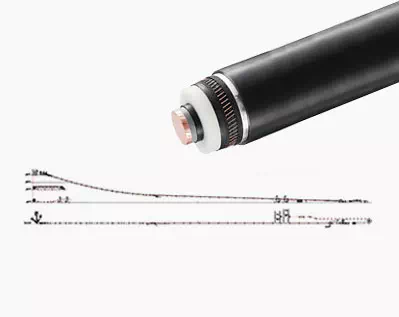

Dry cure CCV lines for Medium / High Voltage cables

-

Triple extrusion line for Insulation of silane-XLPE cables up to 33kv

-

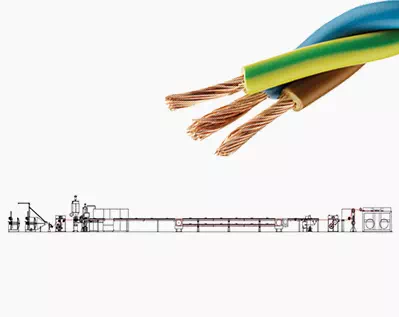

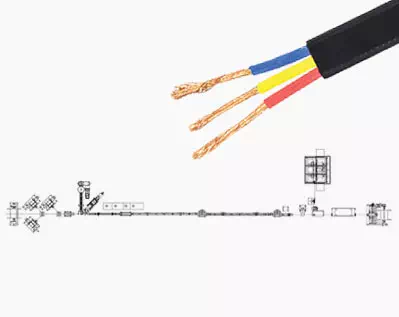

Insulation line for Building wires/Automotive wires

-

Insulation & Sheathing lines for Building wire/Submersible cables

-

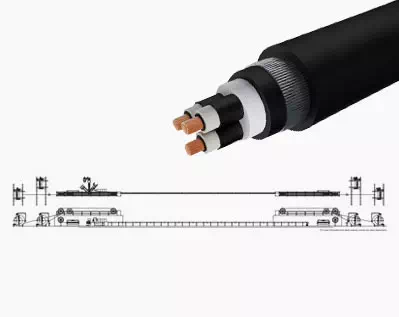

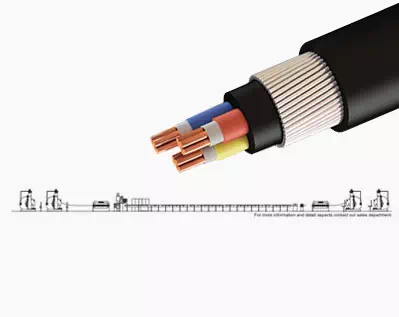

Insulation & Sheathing line for Power cables

-

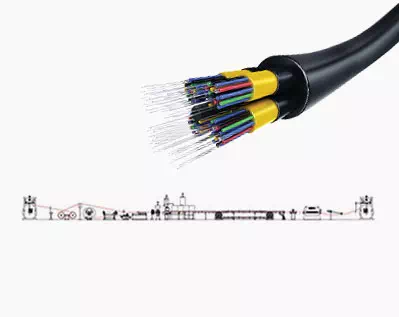

Sheathing lines for Optical fibre cables

-

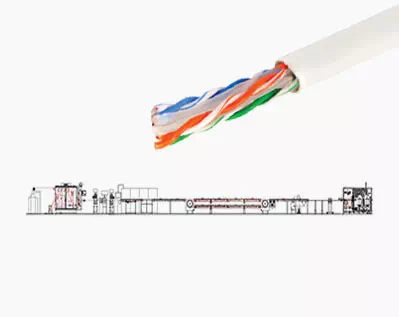

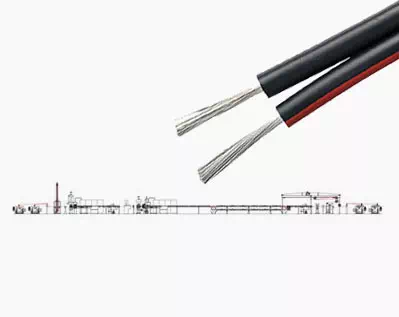

Tandem extrusion line for Lan & telephone wires

-

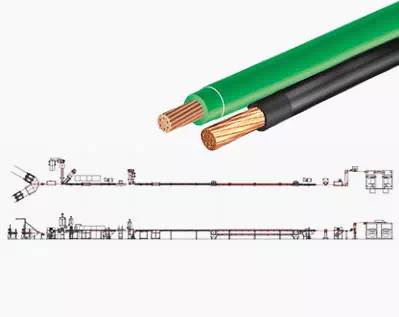

Insulation & Sheathing line for THHN cables

-

Tandem extrusion line for Solar cables

FAQ

Cable Extruder here refers to the machinery that is used in the process of cable extrusion. The process of extrusion refers to the deformation of a material. Under this process, a material undergoes a deformation by applying a force. Due to this force, the particular material flows through an opening. Squeezing out toothpaste from its tube will be an excellent example of the process of extrusion. It is because of this process, that manufacturers are able to easily create products with complex profiles. The process involves meeting different types of materials to be compressive and shear stresses.

Generally, the terms like cables and wires are used interchangeably; however, there is a small difference between both. The difference is that a wire is an electrical conductor but a cable contains multiple conductors or a group of wires that are encased in the sheathing. An extruder machine is a piece of equipment used in the process of extruding wires to further form cables after their extrusion. An extrusion process involves deforming a material by applying force to the material so that it forms the desired shape. This force causes the particular material to flow through an opening.

Extrusion is a manufacturing/ molding process where a base material is forced through a pre-shaped die to create objects with a specific shape and profile. The cable extrusion has a step-by-step procedure. The first step of the process involves placing the raw material which is generally a metal work piece of standard size into the extrusion press. The press is a form of piston cylinder in which metal is placed and pushed with the help of a piston. With the help of a plunger that is fitted into the press, a compressive force is applied that pushes the metal work piece towards the die. The force allows the work metal to flow through the die, which is a small opening of the required cross-section, hence converting it into the desired shape.

Extrusion is a process that is used in multiple industries. Since the raw material for the extrusion process varies among industries, the types of extruders simultaneously vary. There are three basic types of extruders.

- Filament-led Extrusion

- Screw Barrel Geometry extrusion

- Syringe Extrusion

The pioneers of wires and cables industries like Supermac largely opt for Screw Barrel Geometry extrusion. This is because, the process allows the continuous flow of the raw material at a slow pace to avoid breakage or uneven shaping, and that is caused by the sudden hydraulic force, as in the case of syringe extrusion.