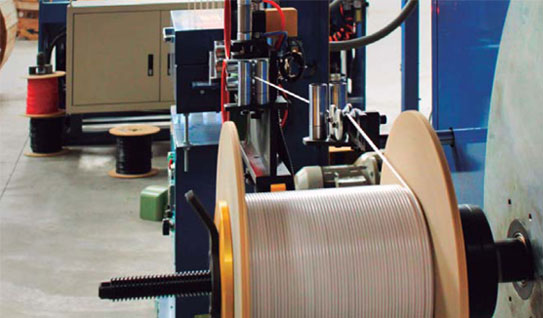

Coiling Machines

Supermac represents Simpacks coiling machines in India, South East Asia, and Africa.

Supermac has tied up with SIMPACKS (USA), to bring out the complete system for control cables and building wires. SIMPACKS is one of the most specialized Automatic Coiling machine manufacturers & suppliers of high-speed coiling machines. SIMPACKS coiling machines can do 3-5 coils per minute. Supermac will also be able to provide the complete system along with the coiling system to building wire manufacturers in India & abroad.

With a core focus on improving and developing new solutions & services, Supermac has once again raised the bar in terms of quality and efficiency and has become one of the best Automatic dual head coiling machine suppliers in India & abroad. The SIMPACKS coiler & spooling machines are easily integrated in line with Extrusion Line. SIMPACKS also offers Accumulator for storage during the time of Stop-Cut-Start of a new coil in Auto Mode.

SIMPACKS- Automatic Coiling & Packaging Solutions

Joining hands with SIMPACKS to emerge as one of the leading automatic dual coiling machine manufacturers and suppliers, Supermac has always been committed to the needs of its customers and is pleased to offer the following Controls options for the Automatic Coiling & Packaging system:

- Ready to work in line with Extrusion line or Rewinding application

- Precision Winding and Tension Control

- Included a precise Digital Counter

- Controlled by PLC

- Color Touch Screen for Operation, Troubleshooting, and Alarms

- Built-in Products Recipe (Saving and recall of Coil Parameters)

- Adjustable Coil height(Optional from the Touch screen)

- Automatic Label (Optional)

- Coiler can process Round, Flat, Solid, Flexible, Telephone, Battery, Armored, Steel, and Special Cable

- Coiler also can process small and short lengths

- Three (3) to five (5) Coils per minute (determined by Coil length)

- The Strap (optional) can be selected Toroid or Diametric way

- Autofilm (optional)

Automatic wrapping & label machine

- Automatic and easy integration with the Coiler Machine

- The machine will operate in Manual Mode or in line with a Coiler

- Wrapping Toroid with PVC or PE film

- Controlled by PLC and Color Touch Screen

- Automatic Label unit applies the Label before the film is applied to the Coil

- Film thickness 0.04 ~ 0.07 mm

Dual spooler machine

- Ready to work in line with Extrusion Line or Rewinding applications

- Customer can use Wood or Plastic Reels

- The machine is capable of making Coils with optional Collapsible Head

Automatic coiler + strap + thermo film shrink

- After finishing Coiling to the pre-set Length, the 4 arms carrier will hold the Coil tight and transfer it to the Strap section Machine will start the next Coil as the finished Coil is at the Strap station

- An automatic Conveyor will move the Coil from the strap station to the Sealing unit to apply the PVC or PE film Bag size can be easily adjusted from the Control panel

- Once the Bag is sealed, it is transferred to the Hot Shrink tunnel. Temperature and Time of the sealed Bag in the tunnel are adjustable from the Control panel to obtain a very food finish.

Accumulator for continuous operation

- In order to have the Automatic Coiling Machine operating in line with an Extrusion line we recommend to install and Accumulator to storage during the time of Stop - Cut - Start of a new Coil in Auto Mode

- SIMPACKS supply Horizontal and Vertical Accumulators to match Cable size and Line Speed Accumulators will operate in Tension or Follower Mode with 0 ~ 10 VDC Output position

- Accumulation capacity custom made to fit the application.

Automatic dual-head coiling machine

As one the leading automatic dual take up machine suppliers, Supermac's dual take-ups are designed for reliable production, high reel change-over facility, and for working independently from line controls, providing an easy adaptation and a fast installation to any line with the following features-

- Ready to work in line with Extrusion Line or Rewinding applications

- Precision Winding and Tension control

- Included a Precise Digital Counter

- Controlled by PLC

- Color Touch Screen for Operation, Troubleshooting, and Alarms

- Built-in Products Recipe (Saving and recall of Coil parameters)

Complete automatic dual reel machine

Supermac, as one of the leading dual reel machine suppliers in India, prides itself on its adherence to the strictest quality control measures while offering complete automatic dual reel machine with the following features-

- Auto conveying for Loading and Unloading Reels

- Reels size from 300mm up to 500mm

- Controlled operation by PLC and Color Touch Screen

- Built-in Products Recipe

Automatic palletizer & stack machine

- Auto conveying and stacking of Coils or Boxes on a pallet

- The number of Coils or Boxes per stack is fully programmable

- You can program the transfer robot to stack Coils or Boxes to the pallets in any configuration

- Controlled operation by PLC and Color Touch Screen

- Built-in Products Recipe (Saving and recall of Stack Parameters)

- Automatic loading and stacking of Coils or Boxes

Pay-Offs

Apart from a wide range of drawing machines, spooling, and coiling equipment, Supermac as a leading Flyer payoff machine manufacturer and one of the reputed Driven Payoff Machine Suppliers, offers different types of wire pay-offs including Flyer, Driven, and Dual. In most cases, their designs and types are individual. Each payoff machine is manufactured using the best grade raw materials, and advanced technology. As a leading dual payoff machine manufacturer, Supermac can meet almost all specifications of payoffs. The company is also well-known as a high-quality Dual capstan supplier both in India and abroad.

FAQ

Just as the name suggests, coiling machines are a part of the extrusion lines that are engineered to coil wires, cables, hoses, pipes, threads, metallic strips, and many other flexible products. These machines come with different applications in a diverse marketplace. A majority of coiling machines are used in the wire and cable industry, optical cable, automotive, medical, aviation, housing, and many more. Wires and sheet metal are mainly rolled on the coiling machine. When needed, these coils will be uncoiled for further processing after being rolled into inventory.

The benefits of the coiling machine by Supermac include:

- Primed to work with Extrusion line or Rewinding application.

- Precision Winding and Tension Control.

- Has a precise Digital Counter.

- Has a Color Touch Screen for Operation, Troubleshooting, and Alarms.

- Built-in Products Recipe (Saving and recall of Coil Parameters).

- Adjustable Coil height(Optional from the Touch screen).

- Automatic Label (Optional).

- Coiler can process Round, Flat, Solid, Flexible, Telephone, Battery, Armored, Steel, and Special Cable.

- Coiler also can process small and short lengths.

- Three (3) to five (5) Coils per minute (determined by Coil length).

- The Strap (optional) can be selected Toroid or Diametric way.

- Autofilm (optional).

The coiling machines are labor-minimizing solutions that complete the extrusion process effectively. In a general procedure, the coiling process is done manually or semi-automatically. However, the coiling machines automize the process to create a synchronous completion of the wire extrusion to the near-packaging point. In other words, the coiling machine fits between the processes of insulation extrusion and labeling of the product packaging to provide automatic coiling support to the wires. Lastly, the take-up and pay-off machines complete the procedure saving you a lot of time and money which you have had to dedicate to the coiling of the extruded products.